The ribbed belt combines the high flexibility of the flat belt with the high performance of the V-belt. The V-shaped parallel ribs are made from a wear-resistant rubber compound. The high strength tension cord is designed for the many applications of

the ribbed belt.

It is embedded in a rubber adhesive mixture and covers the entire width of the ribbed belt. Fibre reinforced, wear resistant rubber compounds ensure quiet operation, oil and heat

resistance and a long belt life.

The small minimum pulley diameters are suitable for drives with high speed ratios as well as slow running drives. Ribbed belts are well suited for the use of back bend idlers, such as in

serpentine drives.

|

Sections and lengths

|

|

| (E)PH | 698 - 2155 mm |

| (E)PJ | 280 - 2489 mm |

| PK | 630 - 2845 mm |

| PL | 954 - 6096 mm |

| PM | 2286 - 15266 mm |

| further dimensions on request | |

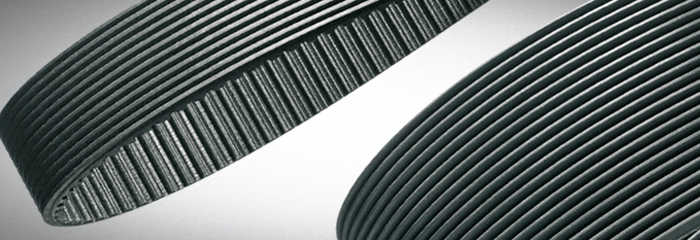

The optibelt OMEGA RB timing belt with an additional PK ribbed belt profile on the top surface of the belt is perfect for use in mills, such as food, cereals, fruit and flour mills, where the drive pulley direction on the top surface is reversible and slip is necessary if the drive jams.

|

Sections and lengths

|

|

| 8M with PK-Back | on request |

Elastic ribbed belt sections EPH and EPJ consist of:

The superstructure is made from a fibre-reinforced rubber mixture. The fibres are laid perpendicular to the direction of belt travel and stabilise the belt during dynamic operation.

The tension cord is a high modulus polyamide

material embedded in a rubber compound and covers the entire width of the ribbed belt.

The rib compound is characterised by high wear resistance and damping properties.

|

Sections and lengths

|

|

| EPH | Belt lengths depend on the section, see the product range. |

| EPJ | Belt lengths depend on the section, see the product range. |

| further dimensions on request | |

|

Sections and lengths

|

|

| Specific sections for special applications (householf appliances / food processors) | on request |

The elastic ribbed belts were especially developed to meet the mechanical requirements for fixed distances between centres. The unique tension cords of high-quality polyamide provide the required elasticity for the ribbed belt and

consequently also increase the permanent resistance even with frequent start/stop cycles.

Elastic ribbed belts of the optibelt CONVEYOR POWER RB series are used in all fields of the transport and logistics industry. Straight

roller track conveyors – curved conveyors – accumulating conveyors – continuous conveyors – sorters – transfer lines – outfeed & infeed systems, semi-automatic & fully automatic storage systems, etc.

With an efficiency

of up to 97%*, the optibelt CONVEYOR POWER is used with transport weights of 1 – 1200 kg depending on the conveying speed and acceleration. The optibelt CONVEYOR POWER was also further optimised for use in curved conveyors.

|

Sections and lengths

|

|

| PH | 236 - 746 mm |

| PJ | 236 - 746 mm |

| PK | 236 - 746 mm |

| EPH | 236 - 746 mm |

| EPJ | 236 - 746 mm |

Ribbed belts unite the great flexibility of the flat belt with the high performance of the V-belt.

Abrasion-proof rubber components allow for smooth running, a degree of oil and heat resistance and a long operational life.

Ribbed belts are suitable for using back bend idlers which are, for example, in serpentine drives.

|

Sections and lengths

|

|

| In order to make a comparison, all common part numbers can be found in our current reference catalogue, AGRO POWER. | |

| RIBBED BELT PULLEYS | standard range, special pulleys on request |

Office # 3R, Laxmi Industrial Estate,

New Link Road, Andheri (West),

Mumbai - 400053. (India)

All Rights Reserved by Power Belt India Designed by Mirackle Solutions, India